STACBOND ALUMINUM COMPOSITE PANEL

A VERSATILE, RECYCLABLE AND QUICK ASSEMBLY PRODUCT.

EVERYTHING YOU NEED TO KNOW ABOUT THE MOST POPULAR MATERIAL IN THE CONSTRUCTION INDUSTRY.

If there is one thing we can agree on within the construction sector, it is that the popularity of the aluminum composite panel has not stopped growing in recent years. Its use has been increasing under the cover of energy efficiency, its low price and its wide constructive possibilities.

This type of material is specially designed for the construction of ventilated facades, both for new construction and for its renovation or rehabilitation. It provides solutions adaptable to all fields of architecture.

In this post you will know everything you need about the composite panel, how it is produced, its main characteristics, finishes, transformed and most popular uses.

MAIN CHARACTERISTICS OF ALUMINIUM

Composition and elaboration of the aluminium composite panel

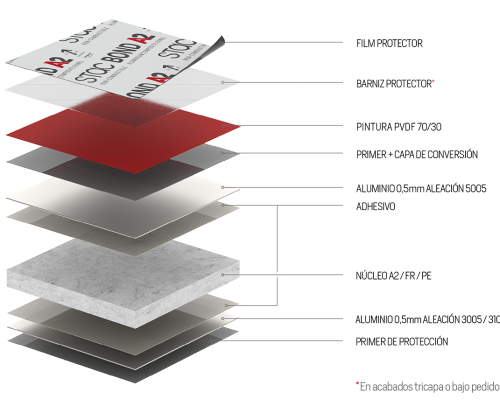

STACBOND composite panel is composed of two aluminium sheets and an inner thermoplastic base core that can hold mineral charge.It is specially designed for new construction ventilated facades as well as for renovation or rehabilitation. Its manufacturing standard is composed of an outer sheet of 5005 aluminium alloy and an inner sheet of 3105.

It is divided into three groups depending on the mineral load of its core (from 0% to more than 90%), and can be incombustible or fireproof and, in some cases (according to UNE 13501-1:2007), classified as A2-s1, d0 and B-s1, d0.

The composite panel is produced by a continuous lamination process, in which a sheet of the material that will make up the core is extruded and compacted between two aluminium sheets that are unwound at the same time. Finally, the flatness of the material is compacted and perfected and a protective film is applied.

Uses of the aluminium composite panel

As I told you before, its most common use is in ventilated facades, a type of coating system in several layers that stands out for its effectiveness in solving the buildings insulation, thanks to the thermal behavior that the facade achieves.

The most curious thing about the ventilated facade is that it allows the creation of a chimney effect between its layers. This chimmey generates a continuous ventilation in the chamber, maintaining a stable temperature that results in greater energy efficiency compared to more conventional systems. Thus, during the summer, the heat is evacuated and the circulating air is renewed. In winter, air circulation is slowed down, preserving the heat.

Among its properties we find:

High dimensional stability

As a material, the composite panel does not present deformations in its dimensioning, whic means that the material remains stable whatever its size without losing its properties

A multitude of finishes

The wide range of finishes that the composite panel allows gives it a great aesthetic versatility. From solid to textured, mirror or wood type finishes, the composite panel can be adapted to almost any type of project

Impact resistant

Recent studies confirm the durability of aluminium in building facades due to its long life and resistance to wear and corrosion

Fully recyclable

The core material and cover sheets of aluminum composite panel can be recycled and reused. Due to its characteristics, aluminium can be recycled indefinitely

Quick and easy assembly

The hanging systems for the assembly of aluminium composite panels are designed to facilitate their assembly on facades in a quick and easy way. In the same way, in case that a cassette is damaged, it is easily replaceable

Light as a feather

The low density of aluminium makes it the ideal material for substructure systems on ventilated facades

CUSTOMISED FINISHES

How to paint the composite panel

Depending on the finish that is sought, the panel can receive multiple types of treatments and coats. Among the most common finishing paints there are:

PVDF (Fluorinated polyvinyl)

It is the most popular finish for architectural applications. In a 70/30 proportion of resin it has a higher folding capacity, as well as a better resistance to ageing and protection against UV rays.

FEVE (Lumiflon)

FEVE is a type of coating with a very similar structure to PVDF, but with greater hardness and less flexibility. It allows to achieving a greater gloss range.

HDPE (High Durability Polyester)

HDPE paint, on the other hand, allows a high range of gloss and some special finishes such as textured surfaces.

COMPOSITE PANEL TYPES

PE

PE panel is composed by two aluminum sheets and an inner core of thermoplastic resins (low density polyethylene). Among its properties, we can highlight its lightness, its flatness, its inalterability to changes in humidity. In addition to this, it can be easily transformed.

It is particularly suitable for ventilated facades, high-durability corporate image, stands and exhibitors, as well as for outdoor applications, among others.

FR

The FR (Fire Retardant) type panel, on the other hand, contains an interior fire retardant core made of thermoplastic resins with mineral charge.

Its reaction to fire classification B-s1, d0 (according to UNE EN 13501-1:2007), makes it a coating material that fulfils most of the architectural applications

A2

In the case of the A2 panel, this is a non-combustible panel composed of a mineral core developed to meet the highest regulatory requirements of fire classification

Its reaction to fire classification A2-s1, d0 (according to UNE EN 13501-1:2007), makes it the ideal cladding solution for high-rise buildings and high occupancy.